Our world is filled today with all kinds of technology buzz words: Industry 4.0,

Blockchain, AI, ML, Digital Twin,… and the beat goes on. As a supply chain leader, you are no doubt either exploring or already utilizing some or all of these. What do each of these have in common? Data! And today there is more data available than last year, and tomorrow there will be even more. In fact, by 2025 some estimates show there will be over 75 billion connected devices on earth. Today it is estimated that we have approximately 20 billion. Simply put, if your organization isn’t investing in these technologies, you are already well behind!

So what does the digitalized supply chain of the future look like? Over the course of four blogs (this being the first introductory blog), I’ll give you a glimpse of the Supply Chain Control Tower of the future. This Control Tower starts with analytics. It’s success is based upon the ability to understand the downstream impact of upstream decisions. Put another way, the Control Tower combines both your internal data (customer revenue, shipment contents, etc.) with external data (like weather patterns, socio-economic trends, etc.) to enable the best decisions to be made, with little to no human intervention.

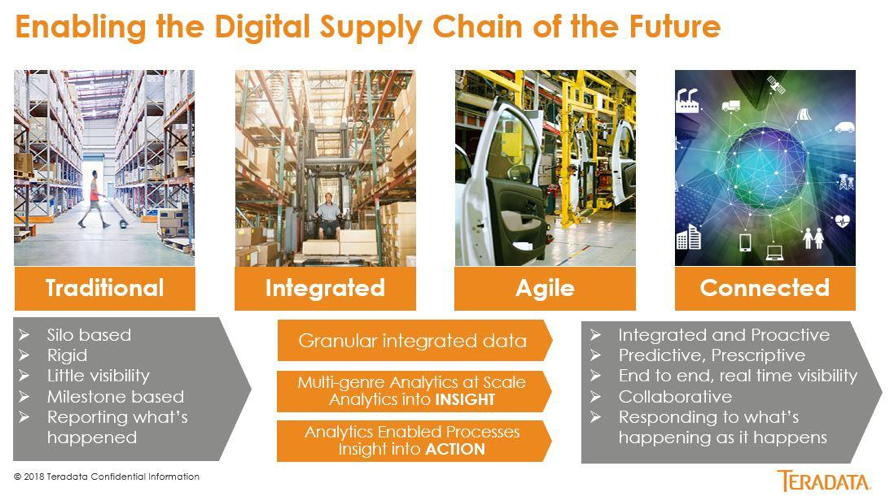

Before diving into the Supply Chain of the Future, it’s important for a quick history lesson. As shown in the graphic below, the supply chain has evolved over the past several decades from being very traditional to integrated and agile. The traditional silo-based approach, with little to no visibility across functions, has gradually changed as more data and information has become available. The real future of successful supply chains exists in connecting the vast amount of data available so that predictive and proactive decisions can be made automatically, with limited or no human interaction required.

So if you believe that the future of the supply chain relies upon full connectivity, then the first step you must take is to harness all of the available data. For example…there are Real-time transit updates from transportation providers, both weather and traffic data from a host of external sources, data from assembly lines as product moves thru the manufacturing processes…this just names a few. The key is to collect the data and begin using it to make decisions.

Now once we have the real-time data, it’s time to combine it with your business data. Take some or all your EXTERNAL DATA (weather, socio-economic, etc.) and combine it with your INTERNAL (or business data). Why is this important? Decisions can’t be made in a silo! External factors will impact decisions, and you need to have the right knowledge about your business. You certainly don’t want to prioritize an inbound shipment at the expense of a product that is destine for one of your top tier customers!

The Supply Chain Control Tower of the future will utilize this integration of both internal and external across three primary areas. These three areas are:

- Supplier Control Tower – This area focuses on the decisions necessary to accurately plan and control the flow of goods into the manufacturing or distribution activities.

- Inventory Control Tower – Here the focus is on ensuring raw materials and finished products are properly tracked and the right level of inventory is in the right place at the right time.

- Logistics Control Tower – The final component area of the Supply Chain Control Tower concentrates on your output to the point of consumption.

In the subsequent three blogs, we will dive deeper into each of these areas. We will explore use cases of where organizations are already using analytics to change the way decisions are being made within their supply chain.

Challenge yourself to understand where you are today…Traditional? Connected?…or somewhere in between? Hopefully this blog series will enable you to develop more ideas of how to move your organization forward towards a more fully digitized supply chain.

Scott Collen is a Senior Business Analytics Consultant for Teradata, providing data analytics consulting to manufacturing, retail, and logistics & distribution organizations. Based in Dallas, Texas, Scott has over 25 years of combined industry and consulting experience including a concentration in Distribution Center Operations Management, Operational Improvement, LEAN/Six Sigma, Supply Chain Management and Engineering, Technology Consulting, and 3rd Party Logistics. Scott’s recent projects include Supply Chain Cycle Time Reduction, Sales Order Forecast Variability Analysis and Supply Chain Network Optimization. Scott has a BS in Industrial Engineering from Texas Tech University.

View all posts by Scott Collen